Ethernet cables are the backbone of modern computer networking, carrying data between routers, switches, computers, printers, and other devices. While pre-made Ethernet cables can be purchased, many network administrators and do-it-yourself enthusiasts opt to create their own custom cables.

Constructing an Ethernet cable is a simple process that only requires a few tools and components. This guide will walk through the step-by-step process for creating both straight-through and crossover Ethernet cables using the common Cat5e and Cat6 standards. We’ll also cover the key differences between cable types, their use cases, and provide handy reference tables.

Ethernet Cable Types

The most widely used Ethernet cable categories today are:

- Cat5 – Max speed of 100 Mbps

- Cat5e – Max speed of 1 Gbps (1000 Mbps)

- Cat6 – Also max speed of 1 Gbps but higher frequency for better crosstalk prevention

- Cat6a – Max speed of 10 Gbps

- Cat7 – Max speed of 10 Gbps

- Cat8 – Max speed of 25-40 Gbps depending on standard used

Higher categories like Cat7 and Cat8 provide faster theoretical maximum data rates but are overkill for most home and small business networks. Cat5e and Cat6 cables are recommended for DIYers as they deliver sufficient performance while being easy to work with.

The main difference between Cat5e and Cat6 is that Cat6 supports higher frequencies so can prevent crosstalk interference better at high speeds. But both can do 1 Gbps (typical home internet speed) just fine.

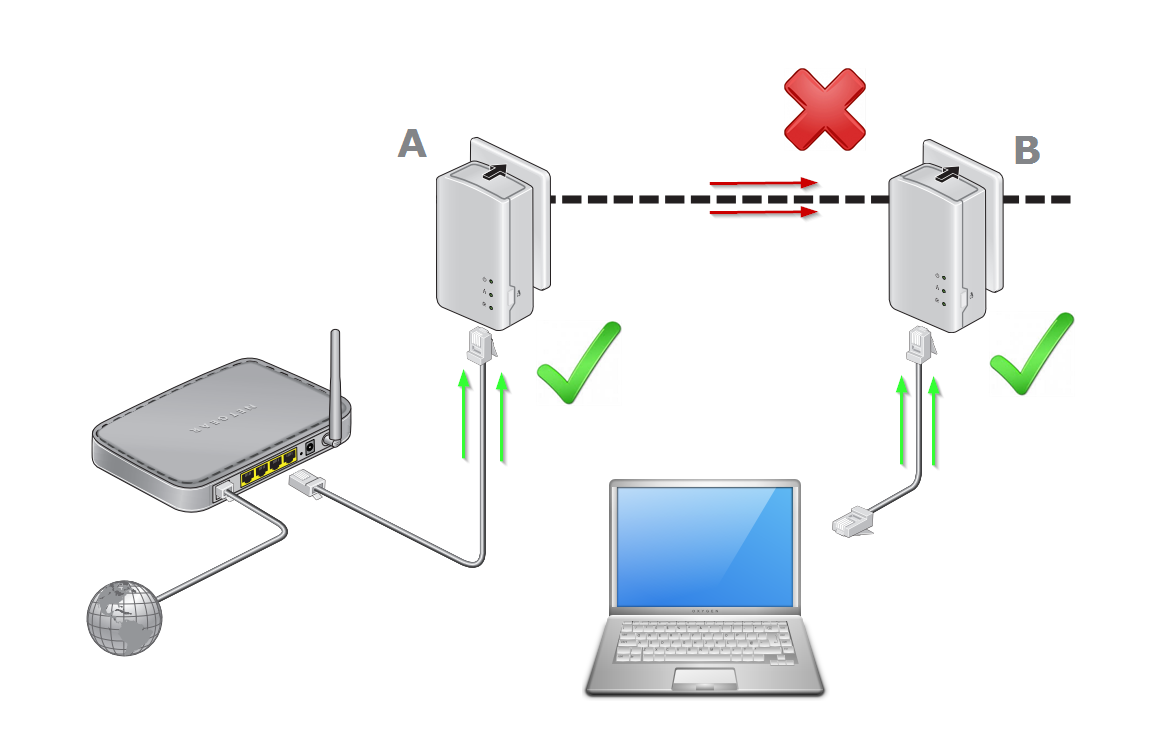

Straight-Through vs. Crossover Cables

There are two main methods for wiring the RJ45 connectors on each end of an Ethernet cable:

Straight-Through

- Identical pinout wiring on each connector

- Used for connecting different types of devices

- Examples: Computer to router, switch to router, etc.

Crossover

- Different pinout wiring on each RJ45 connector

- Used for connecting similar or identical devices

- Examples: Computer to computer, switch to switch

The specific pinouts will be covered later in the guide. Note that modern equipment often has “auto-MDIX” capability to automatically adjust for either straight-through or crossover cables, but it’s still good to understand the wiring methods.

Tools & Components Needed

To get started, you will need the following tools:

- RJ45 connectors

- Crimping tool

- Cable stripper

- Cat5e or Cat6 unshielded twisted pair (UTP) cable

- Cable tester (optional but recommended)

You’ll also want to have the T568A and T568B wiring standards handy for reference.

Step-by-Step Guide

Follow these steps to create a straight-through or crossover Ethernet cable:

- Cut the desired length of Cat5e/Cat6 cable

- Strip off outer jacket about 1 inch from each end

- Untwist and organize the internal wire pairs

- Straighten and line up the wires in the proper order

- Insert wires fully into the RJ45 connector

- Crimp the connector firmly in place

- Repeat steps on the other end using same or different pinout

- Test cable for connectivity (optional)

Refer to the diagrams and instructions below for further guidance.

Straight-Through Cable

To make a straight-through cable, follow the same T568A or T568B pinout wiring order on BOTH ends:

T568A Wiring Order

| Pin | Wire Color |

|---|---|

| 1 | White/Green |

| 2 | Green |

| 3 | White/Orange |

| 4 | Blue |

| 5 | White/Blue |

| 6 | Orange |

| 7 | White/Brown |

| 8 | Brown |

T568B Wiring Order

| Pin | Wire Color |

|---|---|

| 1 | White/Orange |

| 2 | Orange |

| 3 | White/Green |

| 4 | Blue |

| 5 | White/Blue |

| 6 | Green |

| 7 | White/Brown |

| 8 | Brown |

Most Ethernet cables utilize the T568B standard.

Crossover Cable

To make a crossover cable, terminate one end in T568A and the other end in T568B:

This crosses over the transmit (Tx) and receive (Rx) wire pairs, allowing similar devices to communicate.

Creating Your Own Ethernet Cable

Now that you understand the color coding, pinouts, and difference between straight-through and crossover cables, you have all the knowledge needed to start producing DIY Ethernet cables.

Follow the 8 steps listed previously, utilizing the T568A/B references to crimp the RJ45 connectors with the proper wiring order.

When making lengthy runs, be sure to:

- Test cable continuity if possible

- Avoid kinking or tightly bending the cable

- Carefully route through walls/ceilings without stapling

Also keep these additional tips in mind:

- Label both ends for easy identification

- Use snagless connectors to prevent dislodging

- Verify cables work properly once installed

- Coil extra length neatly if needed

Common Applications

Some typical applications for custom Ethernet cables include:

- Connecting a home router to a switch or computer

- Wiring devices in a home office or entertainment center

- Extending network connectivity to other buildings

- Linking computers for peer-to-peer file transfer

- Providing flexible portable connections

Crossover cables can also substitute for wireless in a pinch for direct device-to-device connections.

Cabling Your Home Network

When wiring Ethernet throughout a home, install Cat5e or Cat6 cables for future-proof performance. Solid core cable may be used for permanent runs through walls and ceilings. Standard stranded core cable works for patch cables and temporary connections.

For home use, there is no real benefit to the more expensive Cat7/8 cables. Stick with Cat5e or Cat6 for runs up to 100 meters. Connect devices using either straight-through or crossover cables as needed. Utilize a gigabit router and switches to take advantage of faster 1 Gbps speeds.

Carefully plan home network cabling to link all rooms according to your coverage needs. Install multiple Ethernet jack wall plates to provide flexible access points. Follow best practices for home network installation and properly route cables through walls and ceilings.

Conclusion

Constructing your own Ethernet patch cables is a simple, cost-effective way to create customized networking solutions. This guide covers the fundamentals of cutting, stripping, and crimping Cat5e and Cat6 cables to make reliable straight-through and crossover connections.

Equipped with the right tools and components, you can fabricate any length or style Ethernet cable. While buying pre-made cables is certainly convenient, DIY cables allow for greater flexibility, customization, and cost savings. They also make good weekend projects for the home networking enthusiast.

Whether you need a short patch cable or long Ethernet run for your home network, office, or garage, this tutorial teaches everything needed to DIY your own cables. So put your new crimping skills to work and start wiring!